This article is part of a series called North Carolina’s Gas Blow Out. See the rest of this series as well as other resources on SACE’s Fossil Gas Hub.

Note: As this column was being finalized, a methane gas transmission pipeline owned by Kinder Morgan exploded in an unpopulated area west of Cheyenne, Wyoming, just after midnight on September 21, 2025, sending up a fireball that could be seen for 60 miles. While no one was injured or killed, the explosion did damage nearby train cars carrying hazardous materials, putting first responders at risk.

Methane gas transmission pipelines have crossed the Piedmont region of North Carolina since the 1950s, when the first Williams Transcontinental pipeline was built to move gas from the Gulf of Mexico up to the Northeast. SACE has a whitepaper on pipeline safety issues, but new developments are giving us reason for heightened concern.

- Speed of construction is a dangerous motivator.

- In Virginia, a pipeline inspector was fired for refusing to lie about inspecting pipeline welds.

- In New York, two pipeline inspectors were indicted for falsifying records.

- New pipeline expansion projects are increasingly cramming additional pipelines into existing right-of-ways, creating construction hazards, and encroaching on areas with increasing population density.

- State and federal safety oversight is thin and getting thinner.

This is a recipe for disaster. The question is not when, but where.

Speed of Construction

With multiple gas transmission expansion projects announced in the Southeast over the past two years, pressure is mounting to complete projects as quickly as possible so that specialized crews can move from one project to the next or just return home. One project, Transco’s Southeast Supply Enhancement Project, has even asked the Federal Energy Regulatory Commission to move its approval up by several months, further compressing its construction schedule. Speed has always been part of the pipeline construction ethos. I first heard the term “get the b*tch in the ditch” (hint: it rhymes) at a pipeline construction safety conference hosted by the Pipeline Safety Trust back in 2018. But now we are on a potential pipeline construction spree at a time when the pipeline construction industry is struggling to recruit new workers.

The Engineering Construction Industry Training Board in the United Kingdom published a study in 2024 noting that the sector is struggling to appeal to the next generation. In the US, a simple search for “natural gas pipeline construction” on the jobs board Indeed shows more than 1,000 postings, even before most of the proposed projects have received approval.

These pipelines are large diameter (up to 42” — as big as a patio table) and high pressure (up to 1,440 psi). They need to have no dents, coating problems, or improper welds. Safety and oversight should be more important than speed. Unfortunately, sometimes it isn’t.

Pipeline Inspector Fired for Doing His Job

This need for speed seems to be the motivator for the next issue. Michael Barnhill, a pipeline welding inspector from Texas who was hired by Mountain Valley Pipeline LLC, has filed a lawsuit (Case 1:25-cv-00356) in the U.S. District Court for the Southern District of West Virginia, alleging that he was fired for refusing to lie about the condition of several joints and welds. Of special concern is that in November of 2023, Barnhill was allegedly told to approve the installation of the corroded joints by two different welding inspectors who were his superiors. Mr. Barnhill refused to approve them and refused to falsify records. He was moved to a different section of the pipeline. The corroded joints were installed, and Mr. Barnhill reported the installation to PHMSA.

A few weeks later, Mr. Barnhill discovered a weld that was made without an inspector present. According to the complaint, “Without welding in compliance with stringent heat controls, a gas pipeline is subject to cracking and weld failure.” Again, the same two superiors allegedly ordered Barnhill to approve the weld, and Barnhill reported the illegal weld to PHMSA. MVP cut out the weld and replaced it, but fired Barnhill on the same day. The case is ongoing. It is especially disconcerting that Barnhill was instructed to lie by not one but two superiors (the Lead Welding Inspector and MVP’s Chief Inspector). It appears Mr. Barnhill’s concerns for safety were less important than speed.

NY Inspectors Indicted for Falsifying Records

Even more recently, two inspectors in New York were indicted for submitting fraudulent records between 2016 and 2023. The two men, one of whom is from North Carolina, lied about performing tests on welds throughout New York City and Westchester County — obviously a high-consequence area in the event of a failure. They allegedly engaged in “radaring,” where radiographic images of one weld are reused for additional welds.

The need for speed in the pipeline construction industry is creating careless and unsafe conditions for the communities that live around large-diameter, high-pressure pipelines. We have heard the stories about four allegedly dishonest pipeline welding inspectors in one year. While we must assume that the vast majority of inspectors are honest and take pride in their work, the stakes are simply too high to have any inspectors who are willing to lie about their work.

Too Many Pipelines Crammed Together

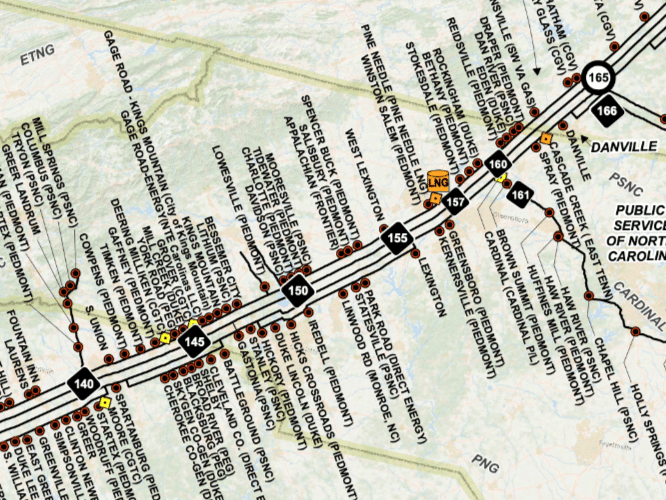

The existing Transco pipeline through North Carolina isn’t just one pipe — it’s actually three and sometimes four pipes of varying widths between 30” and 42”. See Transco’s map below for the stretch in North Carolina.

The Transco Southeast Supply Enhancement Project would add a fourth pipeline in Rockingham County (the Eden Loop) and in Guilford, Forsyth, and Davidson Counties (the Salem Loop). Kinder Morgan/Southern Natural Gas Pipeline and Kinder Morgan/Tennessee Gas Pipeline are doing the same thing — a whopping 500 miles worth — in Georgia, Alabama, and Mississippi (projects called South System Expansion 4 and Mississippi Crossing).

The Interstate Natural Gas Association of America (INGAA) has guidelines recommending that when pipelines are built side by side (called co-location), there should be at least 50 feet on either side of the pipelines to minimize dangerous disturbance of existing pipelines during construction. For four large-diameter pipelines, that would mean a 250-foot-wide right-of-way. In the rapidly growing Piedmont region of North Carolina, this is basically impossible as neighborhoods have grown up around the original pipelines (which typically have only 25 feet between them).

Cramming another pipeline into a right-of-way surrounded by development requires creativity, and not in a good way. The Salem loop is planned to cross the existing three pipelines 20 times along its 24-mile route (11 times in Davidson County, 5 times in Forsyth County, and 4 times in Guilford County, for those counting). One proposed crossing in Davidson County is a mere 1,000 feet from Wallberg Elementary School. A crossing in Forsyth County is near the Veterans Administration Clinic in Kernersville. “Crossing” the existing pipelines means boring underneath the existing pipelines. In at least one place in Davidson County, the proposed project will cross to run between the existing 30” Line A and 36” Line B (see below). Transco is leaving only 25 feet on either side of the new line that is sandwiched between two old lines.

It is hard to imagine how the trenching, stringing, and backfilling will all be accomplished within this tight space without damaging the adjacent pipes. Pipeline installation at the transmission scale looks much like the photo below. Here is a video from Michels Corporation that provides a good sense of just how large these projects are. Very large, heavy equipment is used to excavate the trench and then lay the pipe. This section of the proposed SSEP project is also in a residential area, as the photo above shows. This is concerning.

The Pipeline Safety Trust has voiced concerns about the safety of co-location and the impact it could have on the potential impact radius (PIR), or blast zone. (For more on the PIR, see our white paper.) They shared these concerns in the FERC docket for the SSEP project. What is even less understood is the impact on the blast zone when a pipeline crosses under three large-diameter, high-pressure pipelines — both during construction and after the line is placed into service. What happens if a construction flaw finds ignition and explodes upwards? “Concern” may no longer be the right word.

PST’s biggest concern with the SSEP project – and this is notable – is that of reversal of flow. What happens when gas flow is reversed on a pipeline that has run in one direction — south to north — since the 1950s, and now it is running north to south? We will add to this concern that the gas has a different chemical composition. Fracked shale gas is different than Gulf of Mexico gas. What impact does that have on pipe performance and pipe corrosion? We do not know, and we contend that there should be more study of this issue that does not require North Carolina citizens as guinea pigs.

Federal and State Oversight Is Shrinking

At a time when all of these safety issues are emerging, safety oversight is actually shrinking. The Trump administration is working to loosen pipeline safety rules while also firing members of the Gas Pipeline Advisory Committee. The Senate did confirm a new head of PHMSA on September 17, but this comes at a time when there have been many high-level departures from PHMSA, resulting in a drop in safety enforcement.

At the state level in North Carolina, there are 4,188 miles of gas transmission pipelines and 31,801 miles of gas distribution pipelines. The 31,801 miles of distribution pipelines fall within state jurisdiction, and many miles of intrastate transmission pipelines also fall under state responsibility for safety. North Carolina companies that own and operate intrastate transmission pipelines include Enbridge/PSNC, Piedmont Natural Gas, Cardinal Pipeline, Frontier Natural Gas, and Toccoa Natural Gas. All of these miles fall under the safety purview of the NCUC’s Natural Gas Pipeline Safety Section, which currently has a staff of one Pipeline Safety Manager and five engineers. North Carolina has 100 counties, so this equates to a responsibility of 20 counties per engineer. This seems like a dangerously low staffing level that presents an inherent safety risk.

Not If… When and Where

All of these elements bode very poorly for the long-term safety of these new pipeline construction projects. FracTracker Alliance analyzed PHMSA data and found an average of 1.7 pipeline incidents per day in the United States. Per day. Another incident in North Carolina (and throughout the Southeast) is not if, but when. The latest major pipeline explosion occurred on September 21, 2025, in Wyoming. From media reports, “A natural gas pipeline ruptured and burst into flames early Sunday in southern Wyoming, charring a freight train and lighting up the night sky with a glow seen more than 60 miles to the south in Colorado, officials said.” (emphasis added) No one was injured or killed because this incident happened in a sparsely populated part of Wyoming. What if an explosion visible for 60 miles — from the VA Center in Kernersville to my home in west Durham as the crow flies — happened here? Why would we want to invite that risk into our communities, our neighborhoods, our backyards?

Gas is not our only option. For utilities, building more gas plants is just easy for them. They know how to do it, and they pass the cost along to us, the ratepayers. Gas is the lazy option. Adding solar, onshore wind, battery storage, transmission interconnections with neighboring grids, energy efficiency, demand response, and other distributed resource options requires a little more management, but it is being done in other parts of the country. So by choosing gas plants, we are endangering our communities, while also falling behind in technology advancement, and shouldering increasing costs and increasing risk.